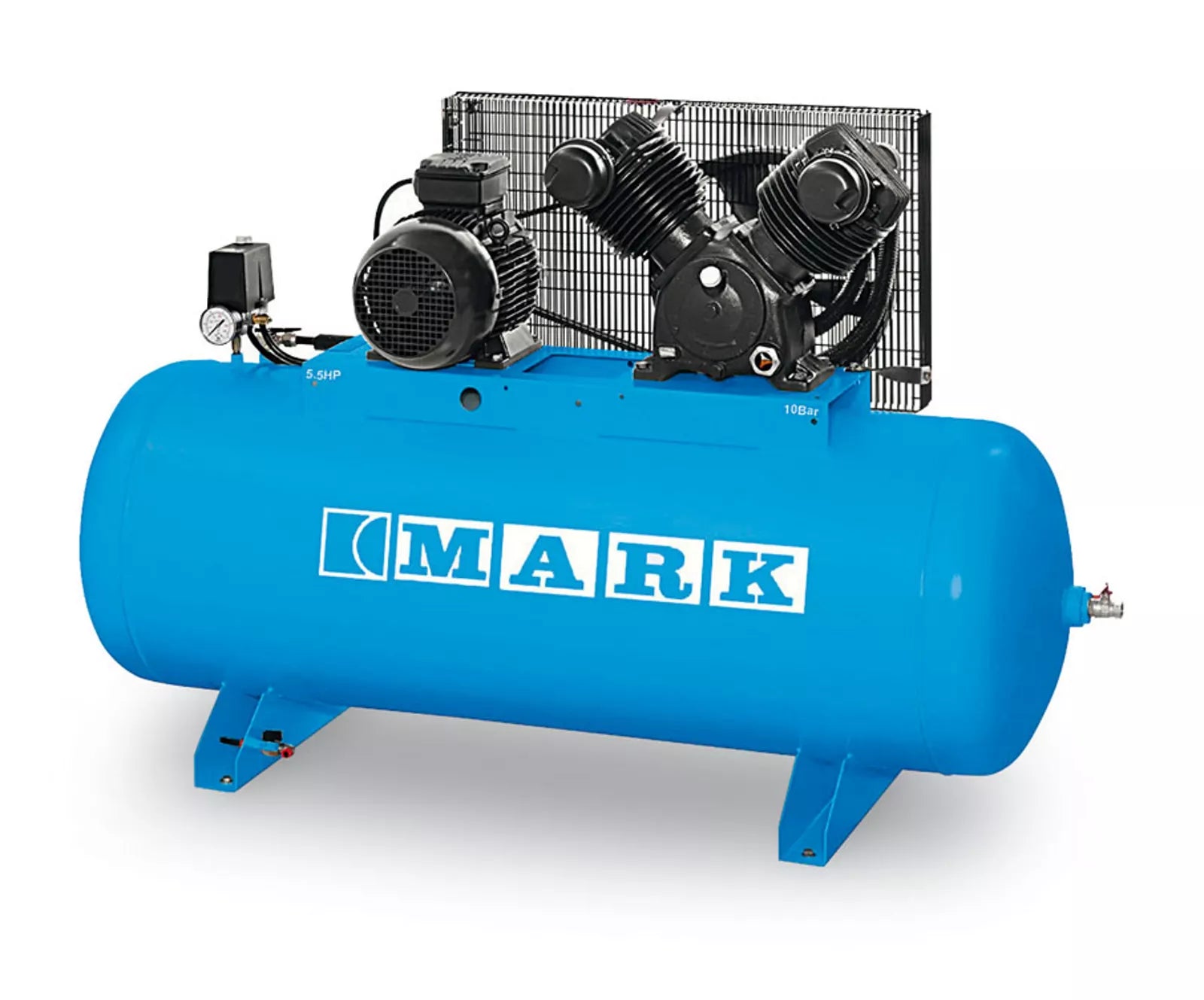

What Is A Piston or Reciprocating Compressor?

"A reciprocating compressor or piston compressor is a positive-displacement compressor that uses pistons driven by a crankshaft to deliver gases at high pressure. Pressures of up to 5,000 PSIG are commonly produced by multistage reciprocating compressors." Wikipedia

A bicycle pump is the simplest form of a piston-driven positive displacement compression, where air is drawn into a cylinder and is compressed by a moving piston. The piston compressor has the same operating principle and uses a piston whose forward and backward movement is accomplished by a connecting rod and a rotating crankshaft. If only one side of the piston is used for compression this is called a single-acting compressor. If both the piston's top and undersides are used, the compressor is double acting. The pressure ratio is the relationship between absolute pressure on the inlet and outlet sides. Accordingly, a machine that draws in air at atmospheric pressure (1 bar(a) and compresses it to 7 bar overpressure works at a pressure ratio of (7 + 1)/1 = 8).

Piston compressors are suitable for small compressed air requirements. One-stage compressors produce pressures up to about 8 bar, while several stage versions produce up to 15 bar.

Operation should be intermittent. An air-cooled piston compressor’s load level should not exceed 60-70%. After 2 minutes of compression, the compressor must rest for at least 1.5 minutes. We recommend keeping the total compression time per day to approximately 4 hours.

Although they have more maintenance requirements, they are very energy-efficient and are available in lots of different configurations in smaller industries, they are most commonly used in:

- Auto repair shops

- DIY-settings

- Workshops

This instructional video from LearnChannel perfectly illustrates the internal workings of piston compressors: